Increasing Throughput with Advanced Loading Machines

There is a term associated with this speed of production, known as Throughput. Throughput is the number of products that can be made in a given amount of time. So, if a factory is able to produce 100 toys in an hour its throughput would also be called as "Key Performance Indicator (KPI)" of that manufacturing process. Advanced Loading Machines for Making More Products One of the methods to make more products is using advanced loading machines. These machines are often constructed so that the products can loaded onto them and moved around more quickly. This perfectly fits in with factories which are able to produce more items within less timeuman effort.

Why Advanced Loading Machines Work More Efficiently

Modern day advanced loading machines have special features that will allow them to provide a better service. On some of the machines, for example they are equipped with sensors that know how much a product weighs and dimensions. This information serves to help make sure they properly load all of your stuff, without going overweight. There are Intelligent sorting line to conveyor goods, and this is in order that there will be no more accidents or injuries. These tech attributes would boost the performance of loading machines with more intelligent ways.

Using New Loading Machines

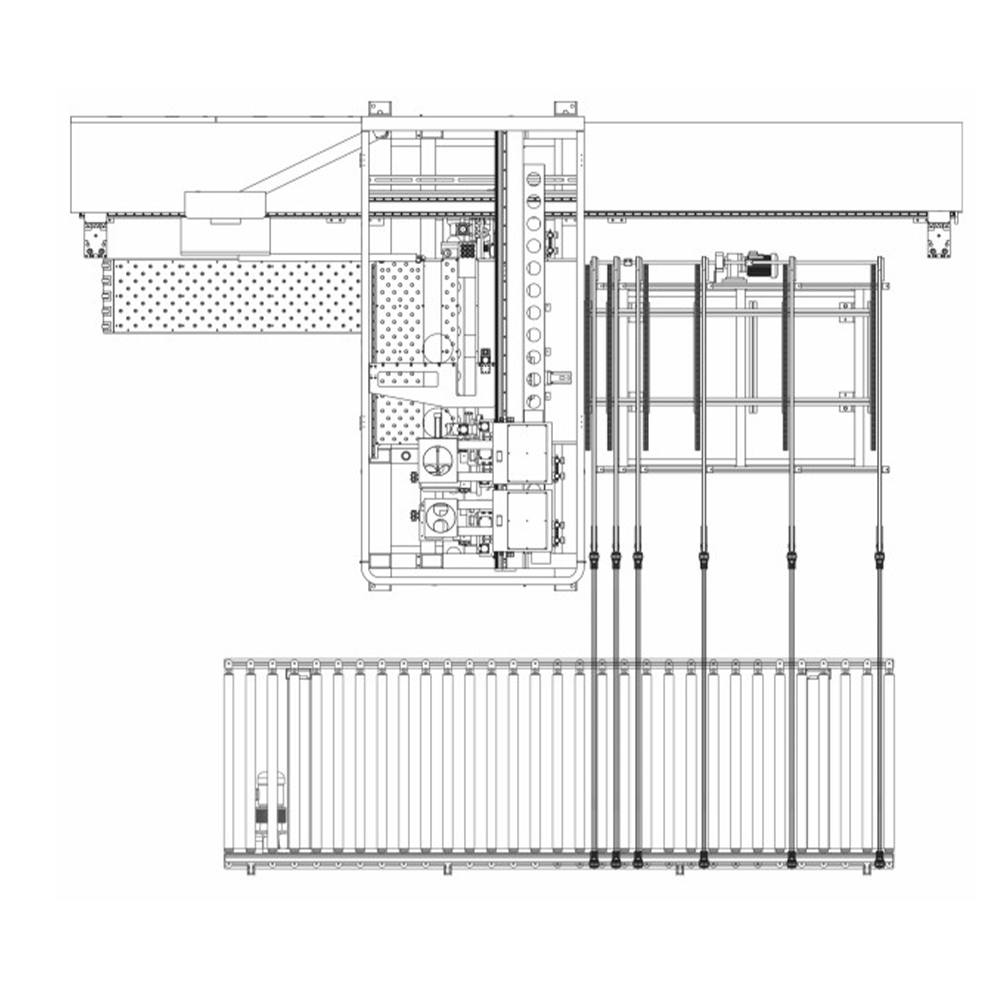

In production facilities, loading machines have been used for a long time as adjacent technology grows and changes. An impressive new variety of machine is the automated loading system. The Packaging production line is capable of loading and unloading products autonomously, so that people do not have to perform this function manually. This allows for infinite factories that can work ceaselessly without the need to take some breaks. Being open round the clock will help them operate even better without stopping, with more output that would enable junkfoodlimited. fr to keep up increasing demand requirements.

The Pros of Advanced Machinery

Production means a lot of things and why there are many reasons to start using advanced loading machines. Well, first as we said earlier, these machines allow more products to become developed in a faster time than on old ways. Cutting process section means more money into the factories pockets. Finally, they are safer for workers: robot tools have safety features to prevent accidents. This is very significant as the safety should always be on top of any work premises. And lastly, these machines can cut down on the man earnings you chop as they will replace several people at once. It reduces the total expense of manufacturing products, which is a plus point for businesses.

Quality Loading Devices Are Tough and Smart

Most of the best loading machines are designed to be efficient and longlasting. Designed to be robust and durable, factories can depend on them for years of service. They use the latest technology to help them simultaneously load products efficiently and deliver quality on voluminous orders. These factories can improve their production abilities and stay updated in the market by investing in such advanced machines.\

With advanced loading machines in your workplace you can fulfill high demands of production fast and safe. Intelligent, secure and costeffective MIR robots to use in hundreds of work shops. As technology gets more advanced the loading machines are going to get better and better, so not only is this good news for the factories; its great news for manufacturers moving forward. The potential for manufacturability over traditional 3D technologies is limitless with the improvements made to these tools.

Comments

Post a Comment